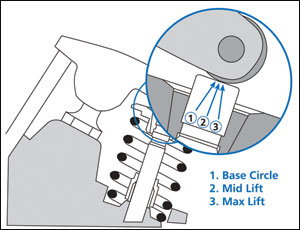

Valve Train GeometryValve train geometry is when the rocker arm tip moves from the intake side of the valve stem tip, across the center of the tip (at approximately mid lift), to the exhaust side of the valve stem tip (at full lift) and back. After you have estimated the required pushrod length using a Pushrod Length Checker, use this guide to check for proper alignment. 1) The first step is to install a solid lifter and an adjustable pushrod. Mark the tip of the valve with a machinist dye or ink. 2) Install your rocker arm and set it up with zero lash. 3) Rotate the crankshaft clockwise several times. take off the rocker arm. The pattern of the rocker tip will be where the ink has been wiped away from the valve tip. The pattern should be centered on the valve tip. If not, adjust the pushrod length to center the pattern.  Measuring Pushrods

Ball-ball pushrods: because of the radiused holes in the ends of pushrods vary in diameter from manufacturer to manufaturer, it is not advisable to measure pushrods by their overall lengths. Instead, it is more dependable to measure them at their 0.140" gauge diameter. In other words, simply find two washers each with 0.140" hole, place one washer on each end of the pushrod and measure the overall distance. Finally, subtract the thickness of the washers to calculate the purshrod's length. |